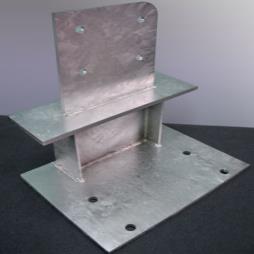

Galvanising Service

The Hot-Dip Galvanising process Materials are immersed in molten zinc at a temperature of 450ºC until they reach the same high temperature as the zinc. The products are then gradually withdrawn to allow excess zinc to drain off hence all fabrications must have sufficient drainage holes. The coated products are then quenched or air-cooled depending on the clients requirements. The appearance of finished galvanised coatings can differ according to the chemical composition of the steel substrate being used. The final effect can range from bright and shiny to a dull grey colour, the dullness is caused by steel containing higher silicon levels.Visit the B. I. G. (Brackets and Bolts) website for more information on Galvanising Service